Specifying Metrix Group's Perforated Metal

Yes, we’re specialist manufactures of perforated metal – and so much more.

We design, manufacture, supply and consult on beautiful, functional, architectural cladding solutions. All we need is your vision. No need to take our word for it, hear what Architects, designers and contractors say about Metrix Group Perforated Metal Systems in these case study videos:

ABN Group Feat. Hassell

Ipswich Grammar Feat. Towill Design

Queen Elizabeth Hospital Feat DesignInc

We Solve Problems and create Solutions

We help archtiects and contractors, who are frustrated with finding solutions for compliant but also aesthetically pleasing perforated metal systems.

We’re family owned, and manufacture locally in Melbourne

We have an in-house design studio to translate our products to your vision

We have the industry’s best customer service and experienced consultants

We have the largest range of patterns and products along with solutions for putting them on your building.

What does the Design Studio offer?

Most things! The in house Design Studio helps translate your design intent into a manufacturable, ready to install system. We can help create:

- Custom panels

- Custom perforations

- Compliant fixing systems

- Recommendations on finishes and installation

- Consultation on functional aspects of open area, ventilation, sunshadinge and wind loading.

Step One | Inquiry

The client contacts Metrix Group and discusses the project budget, design intent, product type, project size, location, and specific design requirements.

Step Two | Engagement

A Metrix Group architectural specialist provides a design proposal that outlines the design and engineering services recommendations.

Step Three | Design Brief

Metrix Group schedules a follow- up client design meeting clarifying specific project requirements including design, engineering, fixing systems, building code requirements and samples.

Step Four | Concept Design

Concept design is created showcasing the custom-designed product, fixing system, and engineering requirements to meet your project building code requirements.

Step Five | Documentation

The client is provided with documentation including project render showing custom façade, fixing system, engineering, and product specification. Physical samples are manufactured.

Step Six | Manufacture

The façade system is manufactured in Melbourne as per design documentation to meet all building code and engineering requirements.

Industry leading range, research and continuing development.

We’re constantly evolving, researching, developing and sharing our knowledge with our architects, designers, artists and builders. We know that somewhere between this page and a consultation with our Design Studio is a solution for your project.

- Architectural Cladding

- Building Facades

- Curtain Walls

- Roof Panels

- Wall Panels

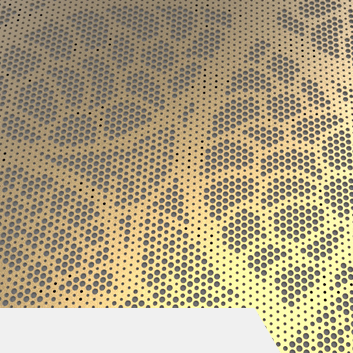

Architectural Specification of Perforated Metal

Architectural perforated metal can be specified according to a number of different parameters. Perforated Metal specification includes:

1. The thinnest and thickest materials we perforate:

| Aluminium | 0.5mm – 6mm |

| Mild Steel | 0.5mm – 2mm |

| Stainless Steel | 0.5mm – 1.5mm |

2. The Standard Sheet Sizes:

Metrix Group offers eight standard sheet sizes as below

| 1800 X 1200 | 2400 X 1200 | 3000 X 1200 | 3600 X 1200 |

| 1800 X 1500 | 2400 X 1500 | 3000 X 1500 | 3600 X 500 |

3. Perforations:

We have over 120 pre-designed patterns in all shapes and sizes ready to choose from. We can assist with customised perforations if you don’t find the style you’re looking for in your architectural projects.

- Standard Shapes (Round, Slot, Rectangle, Square, Triangle)

- Decorative (Patterns and free flowing shapes)

- Picture Perforation (Breathtaking images made up of perforations)

- 3D artform (Formed and dynamic)

- 3D embossed (Shapely and solid)

4. PERFORATION SPACING (PITCH):

As per your design and project requirements. At Metrix group, we can customise the perforation spacing based on how much of the open area clients need and how they wish to use it.

Open areas can be as low as 5% (privacy) or as high as 75% (decoration and ventilation); however, the most common open area is around 50%.

5. Hole sizes:

As small as 1.5mm to as large as you like.

6. Surface finish:

The Metrix Group recommends powder coat finishes for all interior and exterior applications. We also offer mill finished and can consult on anodising.

7. Perforated Metal Maintenance:

View Metrix Group’s care and maintenance instructions on our website here.

We have opportunities for all project budgets

At Metrix Group, we understand how important it is to get the job done well. That’s why we offer a range of products to suit your project’s budget. Whether you need small or large quantities, we make it to order, right here in Australia. Locally made, locally delivered, on time and with no fuss.

Perforated Metal Experts

Our team of experts works closely with our clients to understand their needs and provide them with the most suitable solution. They work together to ensure that the final product meets all clinet requirements, architectural specifications, local environment and industry standards.

Our team comprises highly experienced professionals working on projects across various industries. We have a vast knowledge from material selection right through manufacturing and installation.

Why Choose Us?

Innovation, quality and customer satisfaction are some key factors that set us apart from others.

Metrix Group offers a full range of architectural metal perforation services. We offer elegant and practical solutions to your problems. Our expert staff will be happy to assist you with your enquiry. Don’t hesitate to get in touch with us today.

We’re here to help.

Reasons to choose Metrix Group over other companies who just put holes in metal.

- We offer drafting and design consultation.

- We deliver high-quality products at competitive prices.

- We provide the widest selection of patterns including 3D and embossed.

- We provide product specific installation systems.

- We offer express turnaround times.

- We have an excellent reputation within the industry.

- We have an excellent customer service record.

We look forward to hearing from you!

YOU’VE COME TO THE RIGHT PLACE.

Fill in the form below and we’ll get back to you within 24 hrs.