Architectural Metal Cladding is more than just putting holes in metal.

Our Architectural Metal Cladding is manufactured using the latest CNC punch technology and processes. This provides the flexibility to create a wide product range and the reliability to deliver precision craftsmanship – all with the added bonus of automation.

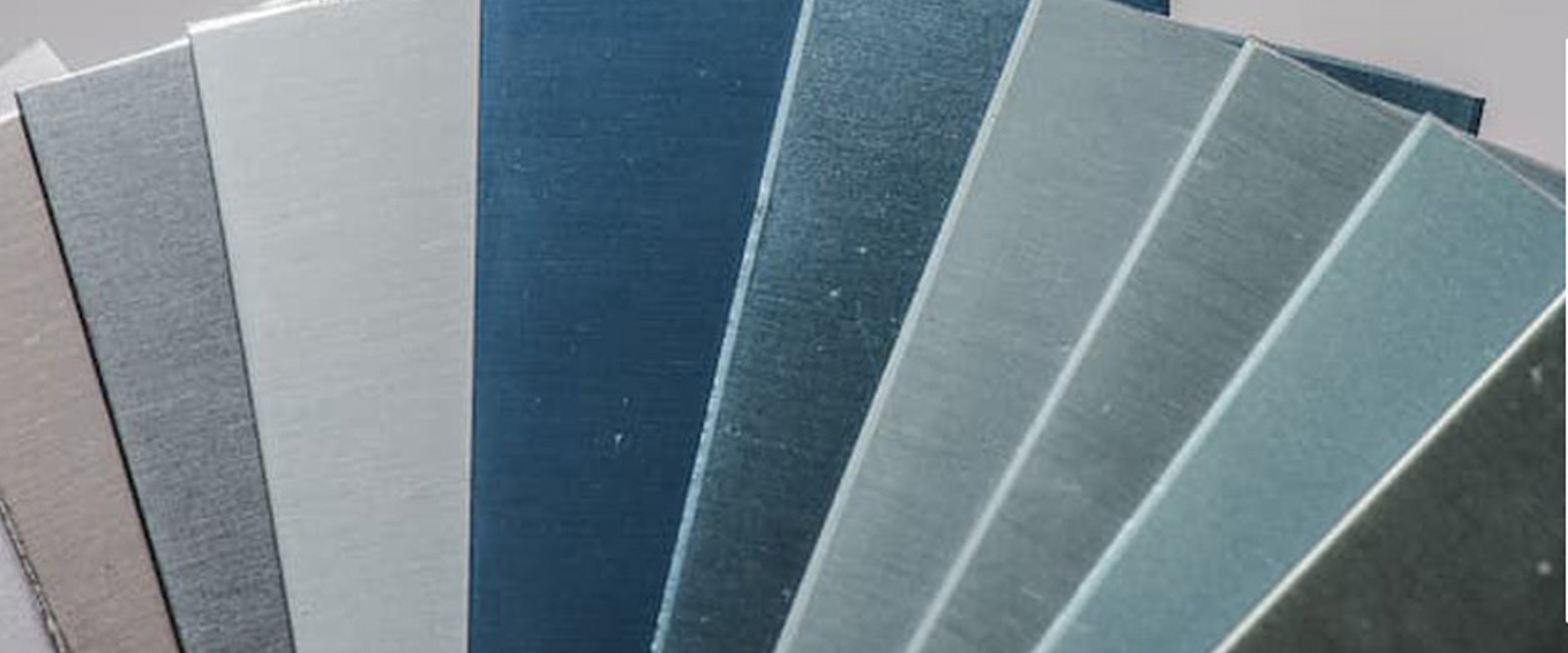

We offer a wide range of architectural metals, including aluminium, mild steel, stainless steel and galvanised steel. We work closely with the best suppliers to provide a range of panel sizes and finishes so you can achieve the perfect finish for your project.

Metal Cladding Systems

Metal cladding systems are designed to not only provide an aesthetic veil, they provide protection for a wide range of building applications. Sun shading, ventilation, light spill and even thermal control are just a few of the protective qualities of the Metrix Group metal cladding systems.

Metal cladding systems are a lightweight, durable and attractive alternative to traditional building materials such as stone or brick. They can be used on the exterior of buildings or inside the structure for acoustic and decorative purposes. This is best exemplified in our 3D artform Emboss range.

Most metal cladding systems are constructed from aluminium or steel, but some products are also available in zinc or copper. The choice of material will depend on the desired finish and budget of your project.

Aluminium is a popular choice when it comes to perforated architectural cladding because it’s lightweight, have a range of useful finishes and are easy to transport. Steel products have a more traditional appearance and are relatively inexpensive compared to other materials like zinc-alum.

Our products include architectural metal cladding, commercial metal cladding, industrial metal cladding, fencing and interior ceiling and walling.

Metal Cladding Materials

Metal cladding materials are available in a range of different textures and colours. The most common metal cladding materials include:

- Aluminium – an aluminium sheet is the most commonly used option for cladding; it’s lightweight and easily cut to size. An aluminium sheet can be powder coated with a high gloss finish to give it a modern look, anodised for a rustic feature or delivered mill-finish.

- Steel – steel is an excellent choice for cold climates where condensation can cause problems with wood. It’s also durable due to its ability to withstand harsh weather conditions.

- Brass – brass is an expressive and beautiful interior cladding. It’s natural shimmer combined with embossed shapes creates an enviable effect.

- Zinc – Zinc is commonly used with copper and aluminium to create stunning patterns and designs on metal cladding products like doors and windows but it certainly lends itself well to cladding.

Why is Aluminium a Popular Metal Cladding Material?

Perforated Metal cladding systems are becoming more popular with the growing demand for aluminium. Aluminium is naturally resistant to rusting or blistering. Aluminium cladding is light and corrosion-resistant, making it ideal for use in areas such as carparks, schools and retail environments.

The main benefits of perforated aluminium metal cladding systems include:

- Lightweight – Aluminium is a third of the weight of steel with a better strength to weight ratio than stainless steel.

- Flexible – Aluminium is easy to shape, form and coat.

- Durable – Aluminium is highly resistant to corrosion, making it suitable for outdoor applications such as schools and carparks.

- Affordable – Aluminium is a relatively inexpensive material, which makes it a reasonable choice for many projects.

- Recyclable – Aluminium is 100% recyclable. Recycling Aluminium uses almost 90% less energy than the primary production process.

Why is metal cladding fantastic for façades?

Perforated Metal cladding is a type of architectural metal used to enhance the surfaces of buildings and other structures. The metal can be decorative or functional, depending on the application and intended use.

Perforated Architectural Metal Cladding can be used on various surfaces, balustrades, interior walls and facades. It can also be used on carparks and commercial buildings such as hotels and office blocks.

- Perforated metal cladding is flexible enough to complement the design of your building and create an architectural statement that will last for years with minimal maintenance.

- Perforated Metal cladding is available in a wide range of finishes and sizes. You can choose from various options, including polished, brushed or satin finishes; textured or smooth surfaces; or even a combination of finishes.

- Architectural Metal Cladding is an excellent choice for high-end buildings where durability, style and ease of maintenance are important factors. It has also been used successfully in applications such as community centres, offices and schools where climability and security are paramount.

- It is a design-led solution to the problems of traditional cladding, which typically conceals building elements and reduces their impact. With Architectural Metal Cladding, you can make the most of your building’s structural and aesthetic potential by using aluminium to create an architectural feature that enhances the building’s architecture, its visual identity and your brand image.

How to use Architectural Metal Cladding on Your Project

Architectural perforated metal can transform an otherwise plain building into something extraordinary.

- Add texture to your exterior: Perforated Architectural Metal Cladding can be combined with other materials such as stone or brick to create a textured façade. It can provide a gateway between materials or older buildings.

- Create unique glazing executions: Perforated Architectural Metal Cladding can be used to shade windows or create dappled light. The material is lightweight and easy to install, allowing you to create custom designs that create dynamic light and shadow play.

- Illuminate and entice: Back-lit perforated metal cladding panels and up-lit cassettes turn intriguing daytime buildings into exquisite evening attractions.

How do I choose the right kind of metal cladding?

Choosing a perforated metal cladding system is an aesthetically subjective venture driven by a technical objective.

A Metrix Group design consultation guarantees satisfaction by helping our clients create models, large samples and best use cases for our recommendations before specifying the final product.

Call or email today to schedule your consultation.

Suggested Read: Perforated Metal – Bespoke Architectural Design Solutions