Having access to in-house engineers have helped Metrix Group provide a genuine full-service Design Studio. They are also responsible for our patented Fixing Systems, Acoustic Ceiling Systems, and many internal software tools.

The perforated façade for each project has to be engineered to suit each project’s specific requirements. Below are the 6 steps that have to be addressed for every project.

The Metrix Design Studio Process

Step One

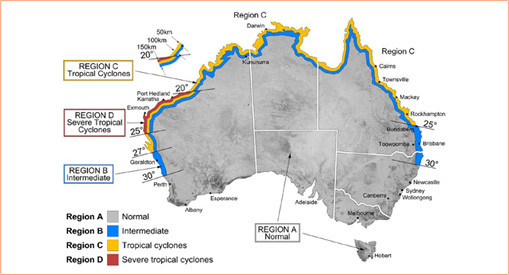

Geographic location

This determines which cyclone region applies to the project.Region A – normal Region B – intermediate Region C – tropical cyclones Region D – severe tropical cyclones

Step Two

Height of building and terrain conditions

Building height and terrain density influence the wind rating. Up to 10 metres in height, above 10 metres, low density, medium density, high density terrain.

Step Three

Application of panels

The product application influences the engineering requirements needed. Carpark cladding, building façade, bridge cladding, operative screens, balustrading, privacy screens, etc. Once the project’s specific requirements have been determined, the product type, pattern, substrate, thickness and installation system can be selected.

Step Four

Product type and pattern

Select the product type and pattern that meets the project’s design requirements.

- 2D Product including Standard, Decorative, Custom and Picture Perforation

- 3D Product including 3D Artform, Embossed and 3D Artform Image

- Acoustic Systems

Step Five

Substrate and thickness

Material type and thickness is varied to suit product type, pattern and installation system. Choose from 5 different substrates.

Step Six

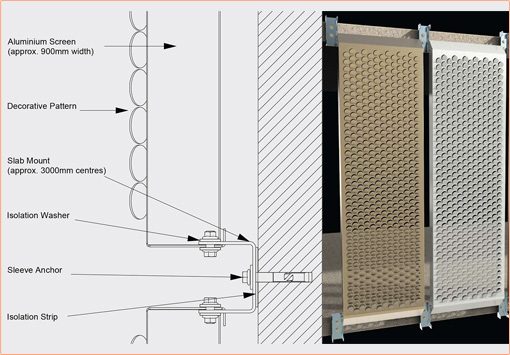

Installation Systems

The product application and project design intent determine the appropriate installation system for selection. Choose from 6 different installation systems.